When a devastating fire destroyed Initiative Foods' (IF) facility in Sanger, California, in 2016, President John Ypma refused to let it spell the end of his family's business. Drawing on his 14 years of experience as a copacker and private label manufacturer in the baby food industry, Ypma recognized a promising opportunity for growth within the industry. The baby food market in North America was expanding substantially, favoring flexible, lighter containers over traditional glass jars.

“It was extremely difficult to see our facility burned down, but within a few weeks, we were ready to rebuild. We began exploring new facility locations and reconnecting with old customers, and realized we had to expand our product range beyond just fruit-based baby food to ensure an even-stronger comeback than before,” Ypma explained. “We planned to incorporate meals containing vegetables, beef and varied nutritious products for children, as well as products packaged in plastic cups and pouches. For that to happen, finding the right retort equipment was crucial.”

The concept of using flexible packages had been considered within the company for some time, but plans could not advance due to IF’s old retorts being unable to handle the process without damaging the product or package. The project was put on hold for a few years until the market demand for flexible packaging emerged. With potential clients increasingly requesting pouches and plastic cups for their food products, IF decided to commit and find the right retort solution.

“We tested new recipes at Clemson University using their pilot retorts, anticipating significant challenges based on previous experiences with flexible packages. However, when we ran our pouches and cups in a Surdry oscillating retort, we saw fantastic results out of the gate. It was amazing!” Ypma said. “We loaded a bunch of containers in and prepared for extensive experimentation to get the pressure right, but surprisingly, we encountered no issues. It was smooth sailing!”

Positive lab test results and Surdry’s strong industry reputation convinced Ypma to resume IF operations using the Spanish retorts. Today, three Surdry oscillating, Steam Water Spray (SWS) retorts are operating in the company’s new facility, and a new static SWS will be delivered in the coming months. Over the last six years, the machines have efficiently sterilized the company’s entire baby food and kids’ meal production.

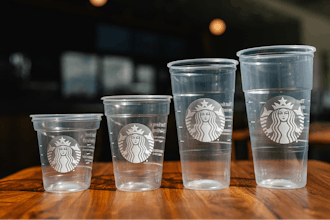

“We've had an excellent experience with the Surdry team from the start. They understood IF's product requirements and addressed specific demands,” Ypma said. “The retorts are extremely flexible — we can run cups and pouches of different sizes and shapes with high quality results. I’m particularly pleased about the water saving capability, which was an important point in our discussions with the local municipality in California”.

In the past, IF utilized full-immersion retorts, requiring substantial amounts of water for sterilization and overloading the sewage system. In contrast, SWS retorts offer greater efficiency and sustainability by providing consistent, even heat distribution from cooling and reusing the water in subsequent batches. The SWS technology, invented and patented by Surdry, combines heating by direct steam injection with superheated water spray.

“We take great pride in our partnership with IF. John Ypma and his team are very committed to high product quality, and we are delighted to contribute to Initiative Foods’ success story,” concluded Julian Stauffer, CEO of Surdry North America (SNA).