WEST LAFAYETTE, Ind. — LyoWave Inc., a high-tech startup, is commercializing innovative microwave heating technologies developed at Purdue University that improve upon traditional lyophilization — or the process of freeze-drying perishable products — by increasing speed, cost-effectiveness and product throughput.

CEO and co-founder Drew Strongrich said LyoWave’s microwave energy innovations open new possibilities for a variety of products.

“Our technology overcomes the historic issues associated with microwave systems such as nonuniform heating, poor tunability, low flexibility and risk of product damage due to the generation of free radicals,” he said.

LyoWave licensed the intellectual property through the Purdue Innovates Office of Technology Commercialization.

Pharmaceutical applications and more

Alina Alexeenko, LyoWave president and co-founder, said lyophilization extends the shelf life of pharmaceuticals, including vaccines, and stabilizes them throughout the supply chain.

“It requires conditions like those in outer space — it is a cold vacuum,” Alexeenko said. “The traditional process is very expensive and time consuming.

“The team at LyoWave wants to push lyophilization further so lifesaving medicines and vaccines can easily reach every corner of the world. We have found a way to apply microwaves to get past some of the key challenges the environment presents.”

Strongrich said LyoWave’s technology enables other innovations.

"There are several alternative and emerging freeze-drying technologies under investigation by the pharmaceutical sector. This comes in response to the growing demand for lyophilized products,” he said. “The LyoWave technology is highly compatible with many of them and serves as a significant force multiplier.”

The National Institute for Innovation in Manufacturing Biopharmaceuticals, or NIIMBL, awarded a team of Purdue researchers almost $1 million to advance lyophilization technologies. LyoWave officials will present at the 2024 NIIMBL National Meeting, which takes place June 25-27.

Although initially focused on pharmaceutical and diagnostic freeze-drying, Strongrich said the technology has multiple applications.

“Microwave heating is a very common industrial process that’s applied over a wide range of industries including food, textiles and chemical production,” he said. “We’re prepared to serve those industries equally as well as the pharmaceutical and diagnostic industries.”

Millrock Technology collaboration

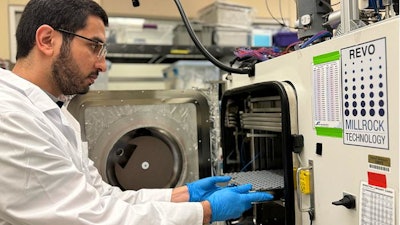

LyoWave has entered into a collaboration agreement with Millrock Technology, an industry leader in innovative freeze dryers for biotech, pharmaceutical and industrial applications from laboratory to production.

Millrock will offer LyoWave’s system for its already installed and new freeze dryers, starting with their popular REVO model. The LyoWave system implements microwave heating for current freeze dryers, which allows users to increase their throughput with minimal changes to existing installations.

“Our innovations will be used to boost Millrock’s freeze-drying systems’ capacity to manufacture diagnostic reagents and bulk lyophilized materials and accelerate process development for new lyophilized drug products,” Alexeenko said.

Millrock CEO and President Martial Pabon said LyoWave’s technology has the potential to deliver high value for the industry by both improving product consistency and reducing drying times.

“LyoWave’s new solid-state microwave technology provides significant improvements in product quality while shortening processing times, which adds significant value to our customers,” Pabon said. “At Millrock, we are always looking at new technologies that advance freeze-drying science. We are totally excited by this collaboration.”

LyoWave’s technology

Dimitrios Peroulis, LyoWave’s co-founder and board member, underlined the significance of advanced electromagnetic technology in this application space.

“Many standard microwave systems operate at 2.45 GHz and use legacy power sources and radiation systems,” he said. “LyoWave provides frequency- and space-adjustable power output at above 8 GHz, which is more effective at heating ice.”

Peroulis said regular microwave designs often use a turntable to counteract hot spots.

“Our technology has flipped this idea and found a way to rapidly rotate the electromagnetic field in random directions, while the product being processed remains stationary, resulting in uniformity throughout the product chamber,” he said. “The microwaves are not only faster but also allow users to take advantage of the unused space inside a freeze dryer.”

Key results of the Purdue research have been published in the March 2024 issue of IEEE Transactions on Instrumentation and Measurement, the January 2023 issue of Journal of Pharmaceutical Sciences and the July 2022 issue of PNAS Nexus.

LyoWave’s Purdue connections

LyoWave was founded by researchers at Purdue University’s College of Engineering. Alexeenko and Peroulis have been jointly leading the team of Purdue researchers who developed the patented and patent-pending innovations since 2016.

Alexeenko is the senior associate dean for undergraduate education and academic programs at Purdue University in Indianapolis and a professor in the School of Aeronautics and Astronautics and the Davidson School of Chemical Engineering. She also co-founded LyoHUB in 2014 with a focus on advancing the science of lyophilization.

Peroulis is the senior vice president for Purdue University Online and the Reilly Professor of Electrical and Computer Engineering. He served as the Michael and Katherine Birck Head of the Elmore Family School of Electrical and Computer Engineering from 2019-23.

Other members of the Purdue research team in the NIIMBL award include Eric Munson, the Dane O. Kildsig Chair in Industrial and Physical Pharmacy and department head; Vivek Narsimhan, the Michael Ott Assistant Professor of Chemical Engineering in the Davidson School of Chemical Engineering; and Qi “Tony” Zhou, associate professor of industrial and physical pharmacy and a University Faculty Scholar.